Due to a technical glitch, the beginning of the recorded presentation was not recorded. Please accept our apologies.

Purpose

Nitrogen is considered an essential macronutrient for plant growth and development. Ammonia, a key part of the nitrogen cycle, arises through two main pathways: naturally through biological nitrogen fixation bacteria and artificially through the Haber-Bosch process. The Haber-Bosch is an energy-intensive process relying on fossil fuels and contributing to greenhouse gases emission. Recovering ammonia from anaerobically digested dairy manure offers a more sustainable alternative to this energy-intensive process, reduces reliance on fossil fuels and mitigates environmental impact. Furthermore, the recovered ammonia can be used as a value-added product to improve soil health and sustainable agricultural productivity. Various technologies have been applied to recover ammonia from dairy manure. However, these technologies were not very efficient in terms of energy consumption, resource recovery, and treatment time. The purpose of this research was to develop a hybrid system where electrodialysis and membrane stripping were applied simultaneously to enhance ammonia recovery from anaerobically digested dairy manure within a shorter treatment period. This approach promotes circular economy through transforming dairy waste into a valuable resource.

What Did We Do?

We developed a three-chamber electrodialysis and membrane stripping (ED-MS) combined system, in which the anode and the cathode chambers were separated by a cation exchange membrane (CEM), and the cathode and trap chambers were separated by a hydrophobic gas-permeable membrane (GPM). The GPM was used for membrane stripping. The authigenic acid in anolyte and the authigenic base in catholyte have been utilized as absorbents and stripping agents to improve ammonia recovery in the ED-MS system. We have applied different current densities ranging from 0 to 150 A/m2 to observe the effect of ammonia removal and recovery efficiency within an 8-hour treatment period. We also observed the maximum rate of nitrogen flux passing through the CEM and GPM for a specific energy consumption.

What Have We Learned?

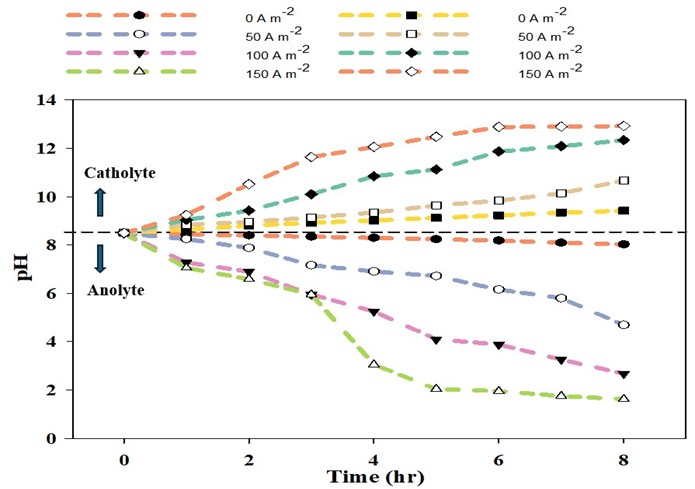

From this research, we have learned that with increasing current density the removal and recovery efficiency of ammonia also increased. The presence of ammonia in the trap chamber increases with increasing treatment time (Figure 1). This ED-MS treatment process demonstrated a broad range of effectiveness for current densities ranging from 0 to 150 A/m2, achieving ammonia removal efficiencies of 42.97% to 99.49% and recovery efficiencies of 11.7% to 75.9% over an 8-hour treatment time. The main reason for this increment is to accelerate the electrolysis process and increase the rate of acid production in the anolyte and base production in the catholyte (Figure 2). The product recovered was ammonium sulfate which can be used as a fertilizer. The highest nitrogen flux through CEM and GPM was identified as 616.1 and 207.6 g-N m-2d-1, respectively, with a specific energy consumption of 45.3 kWhkg-1N-1 (Figure 3). Therefore, this research supports the idea that the ED-MS technique could be a viable solution for sustainable ammonia recovery from anaerobically digested dairy manure on a large scale.

Future Plans

To continue this research, we have a plan to investigate the reaction kinetics of this ED-MS hybrid system. Further, we will develop a novel electrochemical reactor to recover nitrogen and phosphorus simultaneously from dairy waste.

Authors

Presenting author

Ashish Kumar Das, Ph.D. Student, Environmental Science Program, College of Natural Resources, University of Idaho

Corresponding author

Dr. Lide Chen, Professor, Department of Soil and Water Systems, Twin Falls Research and Extension Center, University of Idaho, lchen@uidaho.edu

Acknowledgements

This research was funded by the USDA Sustainable Agricultural Systems Initiative through the Idaho Sustainable Agriculture Initiative for Dairy (ISAID) grant (Award No. 2020-69012-31871).

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7-11, 2025. URL of this page. Accessed on: today’s date.